We, at Alpha e-Stream, rethink the current approach.

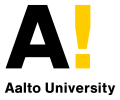

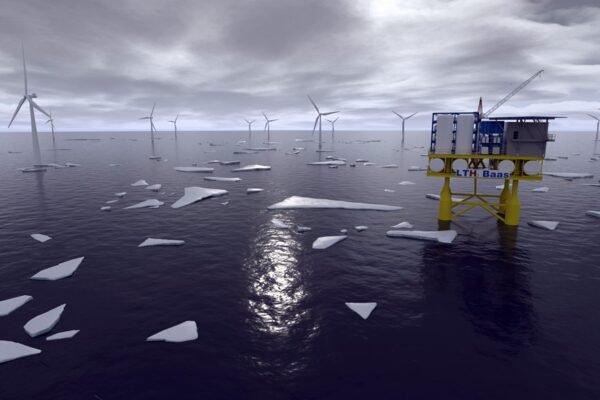

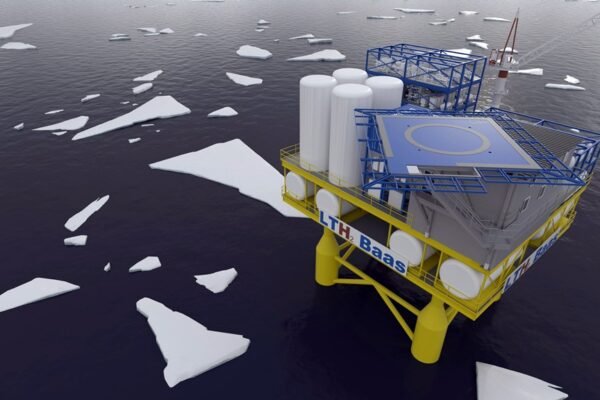

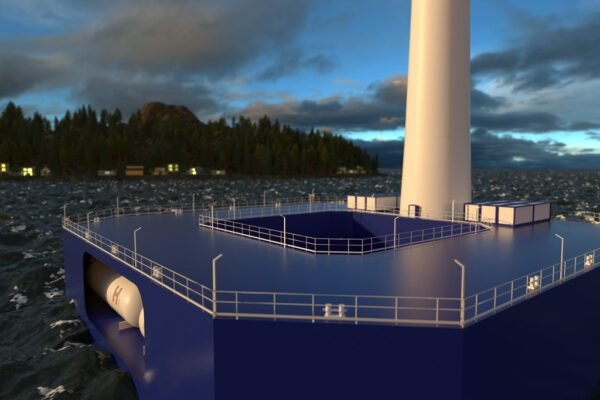

We believe that floating wind turbines can be used not only in deep waters (more than 60m deep) but in offshore in general.

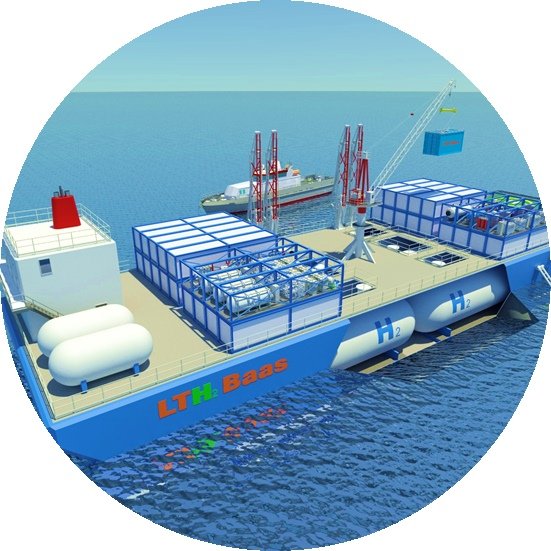

Innovative floating technologies allow to reduce floating wind costs substantially and offer an alternative to fixed foundations.

Floating wind turbines have a number of advantages. For instance, they ease turbine set-up, even for mid-depth conditions (30–50 m), floating foundations generally offer substantial environmental benefits compared with fixed-bottom designs due to less invasive activity on the seabed during installation, reducing installation time just to mention a few.